|

|

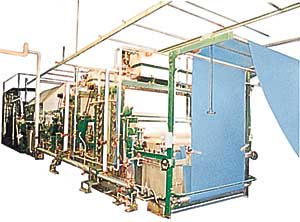

Dyeing

machine Dyeing

machine |

|

INTORODUCTION

KOMATSUBARA, Ltd. have been engaged

in development of various Production facilities for

denim such as continuous yarn indigo dyeing system

since the very starting days of denim production by

yarn indigo dyeing in Japan.

Fortunately, we have good users who gave us advice

and cooperation. Some of them and KOMATSUBARA, Ltd. joined together for a new development

project, with which we have been successful in supplying

such production system that can produce high quality

denim at users.

At present we KOMATSUBARA, Ltd, receive

confidence from users for denim production system.

We are in a position to continue new developement

with the technology for designand production of various

dyeing and finishing systems.

|

| DENIM MANUFACTURING

PROCESS |

|

| YARN

INDIGO DYEING |

|

CREEL STAND to apply

Cones from Spinning Factory. |

|

BALL WARPER capable

300 to 600 yarns in Rope Form. |

|

INDIGO DYEING RANGE

8 to 32 ropes of wound warp yarn are dyed continuously. |

|

RE-BEAMlNG

to make Sheet Form of warp yarns, then to Weaving Factory. |

| CONTINUOUS

YARN INDIGO DYEING RANGE |

*Features

| 1. |

Very firm winding is assured. |

| 2. |

Minimizing yarn cutting. Counter measure will

be taken immediately when yarn breakage with stop

motion. |

| 3. |

Stepless speed change system available for easy

operation. |

|

|

There are two systems in Yarn lndigo Dyeing

a)Rope form dyeing system

b)Sheet form dyeing system

We, KOMATSUBARA lron Works, Ltd. have the system in Rope

form lndigo dyeing.

Features of Rope form dyeing system

| 1. |

In Rope form dyeing system all the disadvantages with

Sheet form will be eliminated: For example in Sheet

form due to tension loaded on each guide roller by number

warps yarn can be tangled otherwise.

This high tension on each yarn will prevent yarn from

being dipped completely, thus uniform dyeing cannot

be guaranteed.

This is one of the disavantages of Sheet form system,

which can be perfectly is eliminated with Rope system. |

| 2. |

Minimized chance of yarn breakage.

No need to stop operation of the machine even case of

the yarn breakage.

Thus, higher efficiency of the facility can de assured. |

| 3. |

Uniform dyeing by newly developed padding system. |

| 4. |

Very stable high quality is assured. |

* Features of KOMATSUBARA'S Rope Form Dyeing System

| 1. |

Beam Stand can be arranged according to

number of required balls and designed space saving structure. |

| 2. |

Low liquor ratio of Dyeing Cistern saves chemical

agents, steam and water. |

| 3. |

Dyeing and Airing properly programmed. |

| 4. |

Most advanced system is adopted in recirculation of

dyeing solution. |

| 5. |

High efficient Drying System. |

| 6. |

Easy maintenance for cleaning of Dyeing Section. |

| 7. |

Specially designed Plaiting-Down System in order to

easy operation and free from danger. |

| 8. |

Rope end can be connected with next rope form without

switching off the machine but reducing the speed. |

| 9. |

Machine can be operated continuously even in case

of a few yarn breakage since yarns are processed in

Rope form so as to ensure uniform dyeing effect. |

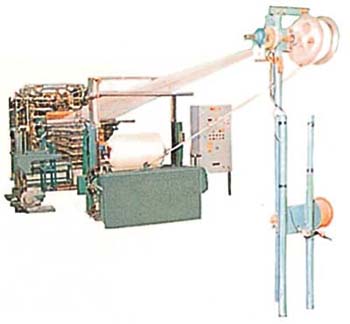

| RE-BEAMlNG

MACHINE |

*Features

| 1. |

Assured such yarn kept uniformed tension. |

| 2. |

Stepless speed change can be arranged on take-up

equipment. |

| 3. |

Easy to remove beam in short time. |

| 4. |

Yarn breakage occured during indigo Dyeing

Process will be found and knotted in this process. |

|

|

| |

|

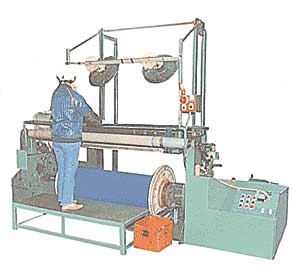

| SlNGEING

MACHINE |

*Features

| 1. |

Uniform singeing is assured since it is developed

for denim singeing purpose.

No need to reduce speed for thicker cloths. |

| 2. |

Can be used for other than denim. |

| 3. |

Safety device and reversing mechanism will actuate

without delay to assure easy operation. |

|

|

| |

|

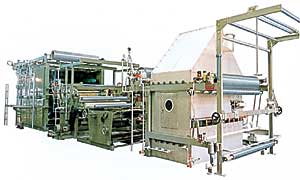

| CONTINUOUS

DESIZING, WASHING & DRYING RANGE |

*Feature

| |

Specially arranged with proper disposition considering

characteristics of denim.

Arrangement of range can be changed according

to production capacity, also easy to put additional

equipments if required for further treatment. |

|

|

| |

|

| SHRINKING

MACHINE |

*Features

| 1. |

Very high efficiency is assured since this machine

is purposed for Denim processing. |

| 2. |

Special Rubber Belt and Felt Blanket are used

for long life operation. |

| 3. |

Operation speed can be adjusted for higher drying

capacity at felt dryer portion. |

|

|

| |

|

FOR CUSTOMERS WHO PLAN TO

INSTALL INDIGO DYEING SYSTEM

| 1. |

Production volume : meters/year or day(dyed yarn or

woven fabric) |

| 2. |

Gray fabric width : inch or mm |

| 3. |

Density of warp : pcs/inch |

| 4. |

Yarn count of warp : Ne. |

| 5. |

Operating days/year : days/year |

| 6. |

Operating hours/day : hours/day |

With the information of above item 1, to 6, we would be

happy to provide you our proposal to meet your requirement

and server for your study.

|